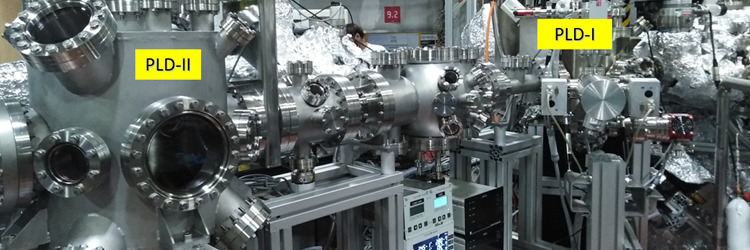

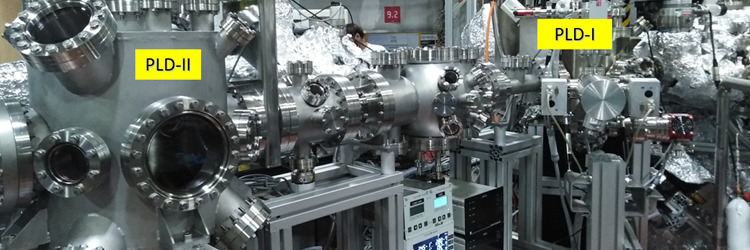

DIGIMAT-Laboratory is consisted with a Dual-PLD deposition systems for the growth of atomically engineered complex materials in form of thin films and heterostructures.

PLD systems equipped with multi-target manipulator which permit two different growth mode - from stoichiometric compound target or in Pulsed MBE mode (using single elements targets). The deposition chambers are equipped with 4-target and 6-target carousels. The dual-PLD is equipped with a KrF excimer ultraviolet and a Nd:YAG infrared laser sources. In-situ RHEED analysis of growth permit to control stoichiometry with precision better than 0.2%. Dual PLD scheme growth system gives huge flexibility for growth compounds, conditions and structures choosing.

The Dual-PLD system is equipped with two-independent deposition systems to grow materials in oxidizing condition (i.e. oxygen) and in UHV/inert gas environment (e.g. Ar, Ne). The ablation process is carried out by an KrF excimer UV-laser and a Nd:YAG solid state IR-laser that can be simultaneously within the deposition chambers. Oxide-PLD is equipped with a near-ambient-pressure RHEED capable to operate up to 1.3mbar. The maximum deposition temperature is 800-850°C (depending on the background gas condition) while the maximum sample dimension is 10 mm × 5 mm for in-situ transferring to APE end-stations and 14mm x 14mm by using flag-style Omicron plates.

Layer-by-layer growth for perovskite compounds is developing for the real-time stoichiometry control. RHEED rocking curve analysis of surface is used for surface/interface engineering. Advanced equipment of growth systems and developed growth algorithm permit to have full control on stoichiometry, stacking and termination in surface/interfaces.

Quantum materials are central for the development of novel functional systems that are often based on interface specific phenomena. Fabricating controlled interfaces between quantum materials requires adopting a flexible growth technique capable to synthesize different materials with high control of structure, stoichiometry and termination. Among the various available thin film growth technologies, Pulsed Laser Deposition (PLD) allows controlling the growth of diverse materials at the level of single atomic layers. In a PLD system, the single atomic species of complex materials are supplied through an ablation process of a target—in form of poly-crystalline powders and/or single crystal—by the irradiation of a focused highly intense pulsed laser beam. Multi-layered heterostructures can be easily engineered by positioning alternate the different targets in the laser focus, in a continuous vacuum condition. PLD shares with other deposition techniques the high cleanness of the growth environment which prevents contamination, as well as the extremely low deposition rate achievable during the growth. Moreover, since the propagation of the plume of ablated materials is inhibited only at very high background pressure (i.e. several mbar), deposition processes at such a high partial pressure are indeed possible. Such a capability is particularly important during the growth of materials containing highly volatile elements (e.g. oxygen, selenium), whose re-evaporation rate can be reduced by increasing the background pressure.

MIUR-NFFA (FOE 2013-present)